Top videos

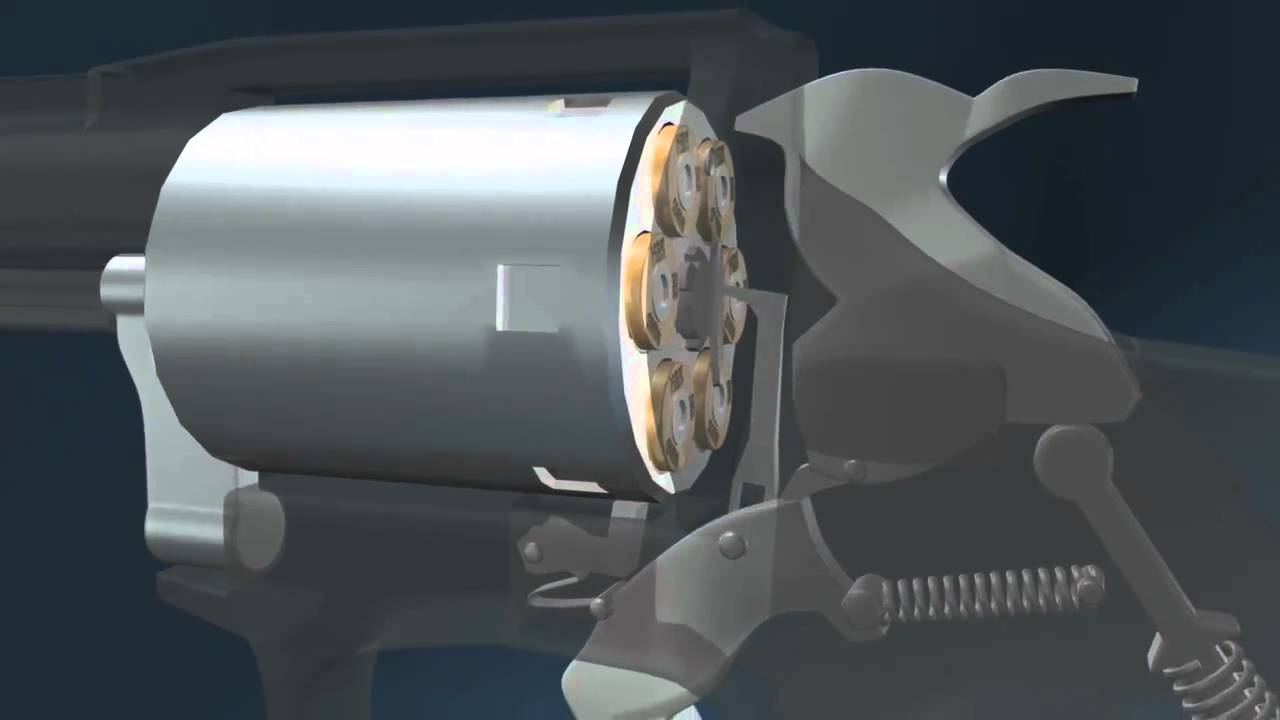

A school project of a simple expository animation of "How a Revolver Works" highlighting the trigger and firing sequences. Reference used from howstuffworks.com

Software used: Maya 2009, Photoshop, After Effects, Mental Ray

Update - September 25, 2020:

Thank you for everyone who has reached out and has provided positive feedback on this animation piece over the past 10 years.

www.andrewlarson3d.com

andrewlarson3d@gmail.com

How to Make Water Pump 4 Inches Engine With Engine 4 Inch Delivery Former Machine

For More Information Please Visit Our Website

http://www.inventedelectricity.com/

View my other videos

how to works bicycle dynamo generator and how to use free energy electric

https://youtu.be/dJnepQE2pHw

How to make Electric Motor Mini science project using dc motor with magnets

https://youtu.be/mEIZe4gVxuc

how to make a free energy generator with hard disk magnets and speaker magnets with motor using 12 v

https://youtu.be/o93TTf49VOY

how to make free energy 220 volts with tv flyback and battery 12 volt 100% real new technology

https://youtu.be/E4IWbX7vkAM

Make Free Energy With Refrigerator Compressor winding And Magnet Motor 12v battery output 220 Volt

https://youtu.be/0lqfiXnkZKk

How to Make 12 Volt Mini Wood Lathe Machine Easy Homemade Project 2018

https://youtu.be/q0RrhPzaHVs

make a wind turbine with motor alternator free energy generator light bulb project 2018

https://youtu.be/SgAMX0U_H88

how to made free energy generator using magnets transformer output 220 volt new project

https://youtu.be/dG9_SF85JEI

Free Energy Generator with Blender Motor 60 watt 220 volt 100% working real homemade 2018 project

https://youtu.be/a__3BncinDQ

how to wind ceiling fan with machine 2018 new videos

https://youtu.be/1WSn3g7Ybk8

Not Free Energy _Make Motor High Power DC Motor High Speed at Home New Project

https://youtu.be/ThP4_osGjE8

Free Energy Recycling 3 Motors Make A Free Electricity Generator 1000%working New Videos 2018

https://youtu.be/J7oGLFB6D8I

Free Energy_ How To Make Solar Panel With CD Flat 100% Working New Project 2018

https://youtu.be/C9pUTeqGcRE

Free Energy _ Motor Converted To a Generator(Alternator) From Washing Machine Motor

https://youtu.be/cIXVM1cm7TA

how to make inverter 12v to 220v 200Watt step by step FULL video

https://youtu.be/mQJvjnboptQ

Make Mini Amplifier 100Watt With 2Sc 2625 Transistor Input 9 Volt Homemade New Project 2018

https://youtu.be/hycU7mYgW40

free energy generator_How to make 100% real100% real without battery by MultiElectric

https://youtu.be/EKWyeL_9Jjg

Free Energy_ Recycling 2 Motors With Flywheel Self Running Generator 100% New Technology 2018

https://youtu.be/XL-ydNHQsjQ

Make a Free Energy Generator from a Dead Printer Motors use Light Bulbs 100 watts 2017

https://youtu.be/9XqOy-ZZ2p4

free energy generator 100 kva Self running 24 hours make free electricity 100% 2018 new video

https://youtu.be/-5KGDaxVkHE

Free Energy Generator Light Bulb 220v 200 Watt With Electric Motor Capacitor

https://youtu.be/UIseUhv8ync

make free energy generator mini best of world 2017 new project

https://youtu.be/hAbZpFUFpDM

Don't forget the subscribe thanks for watching

Axial Flow Pump Moving Car Full auto

Thinking about the problem of getting water pump, this system is going on.

To view the water pump, click this link.=https://youtu.be/-35Y10LaIdM

facebook page = https://www.facebook.com/emransystemmaking

blog = https://emransystemmaking.blogspot.com/

Track: Unknown Brain - Why Do I? (ft. Bri Tolani) [NCS Release] Music provided by NoCopyrightSounds. Watch: https://youtu.be/tcHJodG5hX8 Free Download / Stream: http://ncs.io/WhyDoIYO

Turning Waste plastics and waste glass or vials into concrete paver bricks.

Machine Used:

Plastic Shredder

Glass/Vials Crusher

Concrete Brick moulder

Multi-purpose Mixer

Subscribe to stay tuned for more updates.

Like our page: https://www.facebook.com/fskbuilders/

Follow me on Facebook: https://www.facebook.com/jervinchristian

We are located at Tarlac City, Tarlac, Philippines

Italdraghe presents its new range of Axial Pumps

Test and commissioning of Italdraghe 30" axial pump for irrigation and reclamation for a client in Thailand

With a flow rate of 120.000 L/min , Italdraghe axial pumps are driven by a mobile diesel hydraulic power pack

For more info:

→ Website: https://www.italdraghe.it/

→ Linkedin: https://it.linkedin.com/company/itald...

Please feel free to contact us for further information at +39 335 7019671 or send us an e-mail at sales@italdraghe.it

#dredging #dredginpumps #axialpump #dragaggio #draga #pompaassiale #hydraulicmachine #powerpack

Primitive Technology: Wood Ash Cement - Creating wood ash cement from scratch

Subscribe: http://bit.ly/subPT | Never miss a video! Enable ‘ALL’ Notifications!

More videos, watch me cultivate and cook yams from scratch: http://bit.ly/2L5HmqY

Follow Primitive Technology:

Wordpress: https://primitivetechnology.wordpress.com/

Patreon: https://patreon.com/user?u=2945881

Watch More Primitive Technology:

Latest Uploads: https://youtube.com/playlist?l....ist=PLGnWLXjIDnpBR4x

Pyrotechnology: https://youtube.com/playlist?l....ist=PLGnWLXjIDnpBVRq

Shelter: https://youtube.com/playlist?l....ist=PLGnWLXjIDnpBBsd

Weapons: https://youtube.com/playlist?l....ist=PLGnWLXjIDnpA-XG

Popular Videos: https://youtube.com/playlist?l....ist=PLGnWLXjIDnpAb29

Partial credit for this idea goes to James Keane who I discussed this with on my wordpress site (see conversation): https://primitivetechnology.wordpress.com/2018/03/06/lime/#comment-9736

I developed an experimental cement from made only from re-fired wood ash as its cementitious material. It was mixed with crushed terracotta as an aggregate and formed into a cube. The cement set hard after 3 days and did not dissolve in water after this period.

Process: First I burnt bark and leaves in a kiln at high temperatures to produce well burnt, mostly white wood ash. The ash was then mixed into water and stirred well. The excess water was poured off and the resulting paste was made into pellets and allowed to dry. A pellet was then re-heated in the forge until it glowed about orange hot. This was then taken out, cooled and dropped in a pot of water. The pellet dissolved and boiled due to a chemical reaction with the water. The paste was stirred and crushed terracotta (old tiles from previous projects) was added and mixed to form a mouldable mortar. This was formed into a cube and allowed to set for three days (in the video, a cube made exactly the same way 3 days previously was used due to time constraints). The resultant cube was strong and made a slight ringing sound when tapped with a finger nail. It was placed in water for 24 hours to simulate a very heavy rain event and did not dissolve or release residues into the water.

My current theory: The main component of wood ash consists of calcium in some form (e.g. calcium carbonate, calcium oxide). This can be up to 45% from my research. Calcium is in higher concentration in the bark and leaves of a tree. When the ash is mixed with water, the soluble component of wood ash (10% pot ash) dissolves into the water. But seeing that it does nothing for the cementing process, it is drained off leaving the insoluble calcium (and other components) in the paste. Doing this probably raises the relative percentage of calcium in the paste to about 50% or more. Most of the other 50 % consists of silica and alumina which are pozzolans, materials that chemically react with calcium hydroxide to increase the durability of the cement product. The paste was then made into a pellet and fired again to high temperature to convert all the calcium compounds to calcium oxide. It also reduces any charcoal in the pellet to ash if it hadn’t already been burnt the first time. This step seemed important as un-fired ash pellets only partially hardened and would fall apart in water, though retaining a weak undissolved 5mm thick crust. I can only surmise that re-firing the ash just gave a greater conversion of the calcium components to calcium oxide. The pellet is slaked in water converting the calcium oxide to calcium hydroxide. This cement was mixed with crushed terracotta which may also help in some way that I’m not aware of as I only did this one experiment and did not test other aggregates yet (e.g. sand, gravel etc.). Terracotta is porous and might hold together better than other materials. The mixture is allowed to set in air where carbon dioxide reacts with calcium hydroxide to form calcium carbonate cementing the aggregate together. After this, the cement will not dissolve in water.

Use: I think this material might have a potential use as a mortar holding rocks or bricks together in wet environments where limestone or snail shells are unavailable for making cement. Wood ash is a pretty ubiquitous material to most natural environments inhabited by people using biomass fuels. Wood ash cement turns a waste product into a valuable building material. From my research, wood ash is already being used as a partial replacement for cement in the building industry without decreases in strength of the final product. But I’ve only just started experimenting with it and don’t know its full capabilities and limitations. Calcium content of wood ash differs depending on the species of tree, the part of the tree burnt and the soil it’s grown on. Cautious experimentation is still required before committing to a hut built from this material.

#infratalks #manufacturing #investment #india

Friends, today I'll tell you about 32 upcoming mega manufacturing units in India.

As you all know, India is continuously becoming a global manufacturing hub, and the country facing the most competition in this regard is China.

Let's dive into our topic without wasting much time:

1. Adani Group's Copper Manufacturing Plant in Gujarat

2. VinFast's EV Manufacturing Plant in Tamil Nadu

3. Hindustan Coca-Cola's Upcoming Greenfield Factory in Ratnagiri, Maharashtra

4. Semiconductor Plants in Gujarat, Assam, and Maharashtra

- Semiconductor Assembly and Test Plant in Sanand, Gujarat

- Second semiconductor plant to be set up in Dholera, Gujarat

- Tata Semiconductor Assembly and Test Pvt Ltd (TSAT) to establish a semiconductor plant in Maharashtra, partnered with RRP Electronics

5. Visteon's new Display Manufacturing Plant

6. Maruti Suzuki's new plant in Kharkhoda, Haryana

7. Another manufacturing plant of Maruti Suzuki in Gujarat

8. Ashok Leyland's new e-bus factory in Uttar Pradesh

9. Toyota's new third plant in Bidadi, Karnataka

10. UNO Minda's Alloy-wheel plant in Haryana

11. Tata's new apple plant in Tamil Nadu

12. AMD's new campus in Bangalore with the largest R&D facility in the world

13. Toy-making company Fun Zoo investing in Gautam Budh Nagar TOY Park

14. New laptop manufacturing unit of WISTRON near Bengaluru

15. Saab Manufacturing Unit for Carl Gustaf in Haryana

16. Escorts Kubota's largest Kubota facility in Rajasthan

17. Hero manufacturing unit in Salarpur, Rajasthan

18. PEPSICO's new manufacturing plant in Madhya Pradesh

19. ITC Limited's integrated food manufacturing plant in Madhya Pradesh

20. Sonalika Tractors' manufacturing unit in Punjab

21. UltraTech Cement's investment in Uttarakhand

22. EV manufacturing unit in Jammu & Kashmir

23. GODI India to set up Lithium giga factory in Telangana

24. MIVI's new manufacturing plant in Telangana

25. German EV manufacturing unit in Andhra Pradesh

26. Berger Paints' mega factory in Odisha

27. JSW's new steel plant in Odisha

28. Hong Kong-based Epic Group's new manufacturing unit in Bhubaneswar

29. HPL's new plant in West Bengal

30. Ambuja Cement's new plant in Jharkhand

31. New TCIL ultra-modern manufacturing plant in Jamshedpur, Jharkhand

32. PEPSICO's new plant in Assam

In This Video

New Upcoming Investment In India

New upcoming investment of india in manufacturing sector

UPCOMING NEW FACTORIES IN INDIA

New Manufacturing Plant In India

New Upcoming Company In India

Upcoming all investments in industries

New upcoming industries in india.

Copyright Disclaimer : under Section 107 of the copyright act 1976, allowance is made for fair use for purposes such as criticism, comment, news reporting, scholarship, and research. Fair use is a use permitted by copyright statute that might otherwise be infringing. Non-profit, educational or personal use tips the balance in favour of fair use.

Join this channel to get access to perks:

https://www.youtube.com/channe....l/UCkC5OG_ok21zGdEXe

Follow Us On Facebook - https://www.facebook.com/infratalks

Follow Us On twitter - https://twitter.com/InfraTalksYT

Follow Us On Telegram - https://t.me/infratalksYT

#energy #wind #turbines #energy #ngscience

https://ngscience.com

Electricity is very important to people. We use it to power our homes, cities and trains and cars.

One of the main ways we produce electricity is with the use of a generator. A generator is a device that converts mechanical kinetic energy into electrical energy.

A wind turbine is a very large windmill that uses the kinetic energy in wind to spin its blades. The blades spin a generator that transforms the energy into electrical energy.

Often, particularly in very windy places, many wind turbines are grouped together to form a wind farm. Wind farms can produce enough electricity to power whole cities.

A big advantage of wind energy is that it is a clean and renewable energy source. It does not require the burning of fuels and does not produce harmful emissions in to the air.

There are some disadvantages of using wind energy. The large spinning blades on a wind turbine can kill or harm flying animal like birds and bat. They can produce loud sounds that can disturb natural environments and be annoying to people. And if damaged, wind turbines can be expensive to repair.

Check out our related videos on the advantages and disadvantages of other electricity production methods.

![Chicago Dept. of Streets & Sanitation Elgin Pelican Street Sweeper [04.30.2014]](https://i.ytimg.com/vi/kKmx1EcpDrQ/sddefault.jpg)