Top videos

The German state of Baden-Württemberg boasts an unusually large number of local companies that have made it big on the global market. That's in large part due to the creative and entrepreneurial spirit of its residents. Made in Germany takes a look at how so many local companies have taken little-known products and turned them into export hits.

Read more: http://www.dw.de/program/made-....in-germany/s-3066-97

№28: The best business machines for mini production! Top 25 manufacturing business ideas 2024.

👉More New Business Ideas and Info:

- https://whatsapp.com/channel/0....029VaVlXqnLSmbSxrqoP

- https://t.me/businessideas_new

00:00 Start

00:08 Honey Spoons

00:33 More Business Ideas

00:50 Facade Thermal Panels

01:19 Floor Laying Machine

01:47 Holiday Candles

02:18 Disposable Slippers for Hotels

02:51 Wooden Spoon, Fork, and Knife Manufacturing

03:21 IdliBot

03:57 Metal Picket Fence

04:27 Spring Coiling Machine

05:01Packaging Printing

05:30 Feed for Bottles

05:58 Popcorn Machine

06:27 Foam Cutting

07:03 CNC Machine for Box Production

07:29 Egg Tray Production

07:54 Cup Filling and Sealing Machine

08:26 Bottle Blowing Machine

08:55 Cupcake Production

09:19 Laser for Decorating Mirrors

09:45 Mini Excavators

10:14 Protein Balls

10:44 Metal Chip Briquetting

11:17 Gummy Candies

11:45 Toilet Paper Production

12:18 Building Block Production

Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than one required for processing into dimensioned lumber by a sawmill. The log is laid horizontally and rotated about its long axis while a long blade is pressed into it, causing a thin layer of wood to peel off (much as a continuous sheet of paper from a roll). An adjustable nosebar, which may be solid or a roller, is pressed against the log during rotation, to create a "gap" for veneer to pass through between the knife and the nosebar. The nosebar partly compresses the wood as it is peeled; it controls vibration of the peeling knife; and assists in keeping the veneer being peeled to an accurate thickness. In this way the log is peeled into sheets of veneer, which are then cut to the desired oversize dimensions, to allow it to shrink (depending on wood species) when dried. The sheets are then patched, graded, glued together and then baked in a press at a temperature of at least 140 °C (284 °F), and at a pressure of up to 1.9 MPa (280 psi) (but more commonly 200 psi) to form the plywood panel. The panel can then be patched, have minor surface defects such as splits or small knot holes filled, re-sized, sanded or otherwise refinished, depending on the market for which it is intended.

Plywood for indoor use generally uses the less expensive urea-formaldehyde glue, which has limited water resistance, while outdoor and marine-grade plywood are designed to withstand moisture, and use a water-resistant phenol-formaldehyde glue to prevent delamination and to retain strength in high humidity.

Video Credit: www.westfraser.com

Join 'Engineering World' like many others to get access to special perks:

https://www.youtube.com/channe....l/UCh2wZoBynUkHmTX2G

Also, kindly consider subscribing to our channel if you liked the video: https://geni.us/SubscribeChannel

Watch some of our other interesting manufacturing videos:

How Cement Is Made?

https://youtu.be/RcrMBYsB93E

How LUXURY Rolls-Royce Cars Are Made ?

https://youtu.be/BVvnSzMqI3M

How Jigsaw Puzzles Are Made?

https://youtu.be/nylElsB9MkE

#aloobhujiya #megafactorymaking #karnalstreetfood #foodfactory #streetfood #indiaeatmania #indianstreetfood #aloobhujiyafactory #bhujiyarecipe #localfood #youtubeshorts #aloobhujiyamaking

Address: Plot No. 36, 39, 40, 41, Agro park, Kunjpura, Karnal, Haryana(India)-132023

Gps Location: https://goo.gl/maps/acoMNaXpZtauBALt8

Contact Details: +91-7206743742, +91-7082205901

Social Media Platforms @INDIAEATMANIAFOOD

Youtube - Subscribe to us Now:

https://www.youtube.com/channel/UC5vQ...

Facebook - Like us Now:

https://www.facebook.com/indiaeatmani...

Instagram - Follow us Now:

https://www.instagram.com/india_eat_m...

Website - Subscribe to Us Now:

https://www.indiaeatmania.in/

Business Enquiry - Mail Us:

hey@indiaeatmania.in

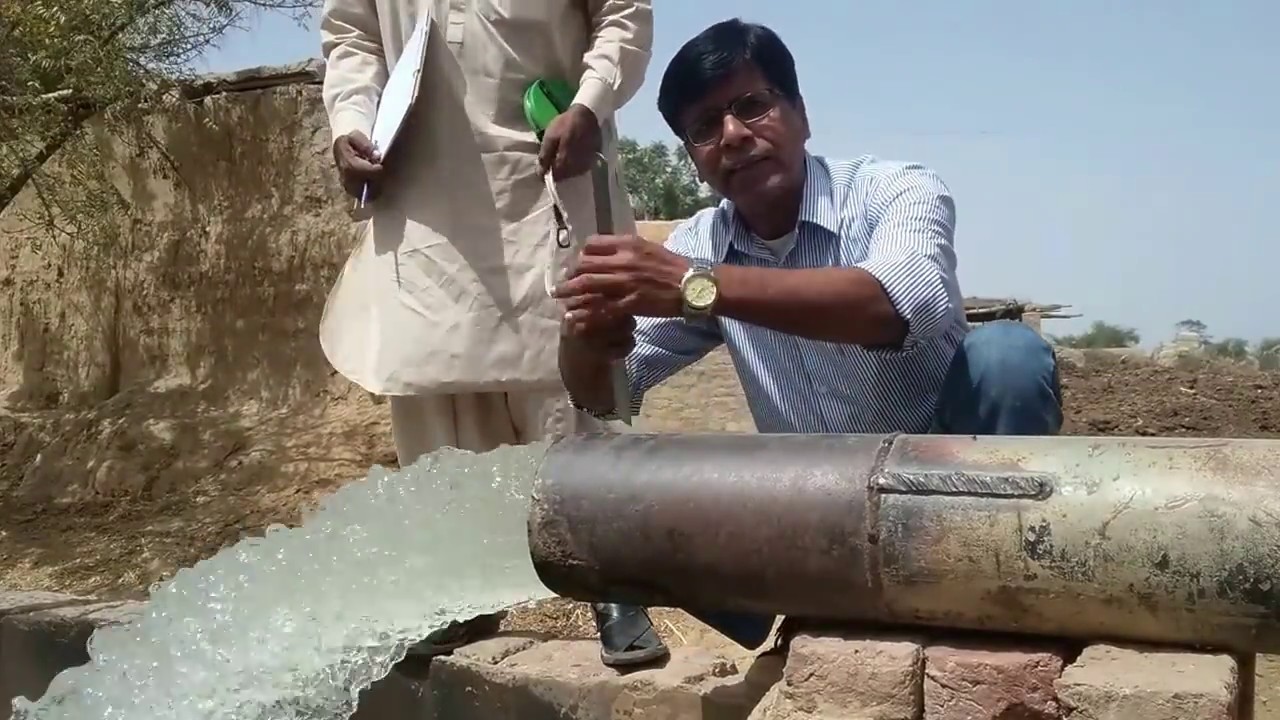

How to Make Water Pump 6 Inches With Engine Farmer Machine How To Make Water Pump 6 Inch Machine

For More Information Please Visit Our Website http://www.inventedelectricity.com/

#Free_Energy_Generator #free_energy #energy #mobile_Charger #science #project #Technology #New_Technology

Mega Manufacturing: Pierce - Fire Truck Manufacturer | 4K Engineering Documentary

What is created here is intended to save lives for once: Pierce Manufacturing: the world's largest manufacturer of fire trucks.

It is the largest manufacturer of fire trucks in the world: Pierce Manufacturing in Wisconsin, USA. 1400 trucks are being built here every year – and each truck is one of a kind. Customers determine every detail from the first sketch on the 3D model to the finished truck. More than 13,000 individual components - most of them laboriously crafted by hand - are turned into an absolutely individual fire-fighting vehicle. Even the lettering and coats of arms so popular in North America are the result of Pierce's manual work with brushes and genuine gold leaf. All this is only possible with a lot of experience. The three thousand employees have on average twelve years of professional experience. After all, not just any product is manufactured here, but in case of emergencies their quality is a matter of life and death. The demands placed on a fire -fighting truck are correspondingly high: heavy as a truck, it must nevertheless be extremely manoeuvrable and fast.

Take a mega-frame, a cab equipped with lots of high-tech, a high-performance water pump and a gigantic ladder: We accompany the production of a popular Enforcer fire truck from the very first step - the construction of the chassis - to the final acceptance by the customer. One of the highlights is the assembly of the TAK4 wheel axle. Developed in the military sector, it enables cornering at top speed without tipping over.

After approximately three months of production, the grand finale is the installation of a gigantic 33-meter turntable ladder on the roof of the Enforcer. A nerve-wracking task for the workers. Using two crane winches, they have to install the component, which weighs tons, with millimetre precision. No cable must be damaged. The final inspection shows whether the installation was successful. Then the customer receives his very own personal emergency vehicle.

▬▬▬▬▬▬▬▬▬

Subscribe Free Documentary Channel for free: https://bit.ly/2YJ4XzQ

Facebook: https://bit.ly/2QfRxbG

Twitter: https://bit.ly/2QlwRiI

▬▬▬▬▬▬▬▬▬

#FreeDocumentary #Documentary #MegaManufacturing

▬▬▬▬▬▬▬▬▬

Free Documentary is dedicated to bring high-class documentaries to you on youtube for free. With the latest camera equipment used by well-known filmmakers working for famous production studios. You will see fascinating shots from the deep seas and up in the air, capturing great stories and pictures from everything our beautiful and interesting planet has to offer.

Enjoy stories about nature, wildlife, culture, people, history and more to come.

Energy companies around the world are storing wind energy with wind turbine farms and channeling it to our homes as electricity. But did you ever wonder how these wind turbines work?

Do onshore and offshore wind turbines work according to the same principle?

If you want to get the answers to such questions and learn more about how wind turbines work, watch our video.

To get the latest science and technology news, subscribe to our newsletter “The Blueprint” at https://bit.ly/3BDdN5e

#engineering